Tube manufacturers require high quality raw material inputs in quick time for efficient tube manufacturing. Our manufacturing process utilizes the latest technology and modern equipment’s for producing high quality ERW Pipes.

Steel strip in coil, which has been slit into the required width from wide strip, is shaped by a series of forming rolls into a multiple length shell. The longitudinal edges are continuously joined by high frequency resistance/induction welding. The cut pipe is straightened and squared at both ends. These operations are followed by ultrasonic inspection or hydrostatic testing.

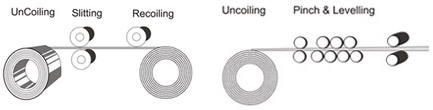

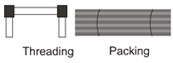

Slitting Process: HR Coils are slitted to pre-determined widths for each and every size of pipes.

Uncoiling, End Shearing And Welding: The slitted coil is uncoiled at the entry of ERW mill and the ends are sheared and welded one after another. This results in a single endless strip.

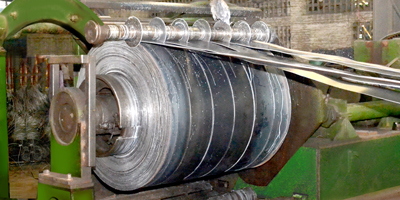

Forming: The steel strip is made to pass through set of forming and Fin rolls and is molded in a circular shape.

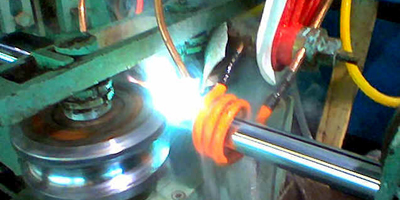

Welding In this stage, the open edges are heated to the forging temperature through high-frequency, low-voltage, high current and press welded by forge rolls making perfect and strong but weld without filler materials.

De Beading The outside and inside surface (if needed) is flushed by removing the excess weld through tools.

Sizing The pipe is then passed through set of sizing rolls for achieving dimensional accuracy as per standard requirement.

Cutting In cutting stage, the pipes are cut to required lengths by flying cut off disc/saw cutter.

End Facing And Beveling This is usually stage, where the pipes ends are faced and beveled by the end facer. These plain ended tubes is hydraulically tested and further go for processing such as galvanizing, threading etc.

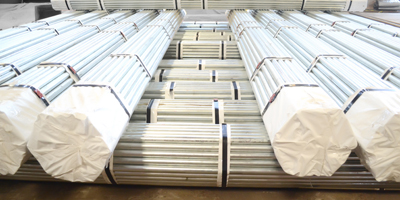

Galvanizing The Galvanized Pipes are manufactured using steel and then coated using the process of galvanizing. These pipes are thoroughly tested and examined in accordance with international standards. The pipes are available in several standard as well as customized sizes, widths and thickness as per the specification provided by our clients.

Packing Finished pipes are bundled in desired number of pieces as per customer's requirement and packed properly to ensure safe storage until delivery.

Corporate Social Responsibility has always been an integral part of Vishwas Tubes. We define social offering as quality products to our client's.

Providing value-based services extends not merely to the provision of high quality products but also to the implementation of a system which benefits society & encourages sustainability.

At Vishwas Tubes, corporate team social responsibility is not just a duty, it is the way, we believe in working together as a team Social responsibility is a guiding principle of all our business practices. Through various initiatives and drives we aim to provide sustainable value-based resources to societies.

- Promise equal opportunity to every employee, and not discriminate among them on the basis of their religion, gender, race, color or language

- Take good care of the environment around us

- We shall commit what we can deliver and deliver what we have committed

- Plant tree saplings to re-energize wastelands & create green cover

- We shall not, through any action or communication, change customer expectations from existing and agreed contract

- Organize awareness drives among people for family planning, literacy and safe & healthy working environment

- We are constantly educating our workers and giving them incentives to keep the environment clean.